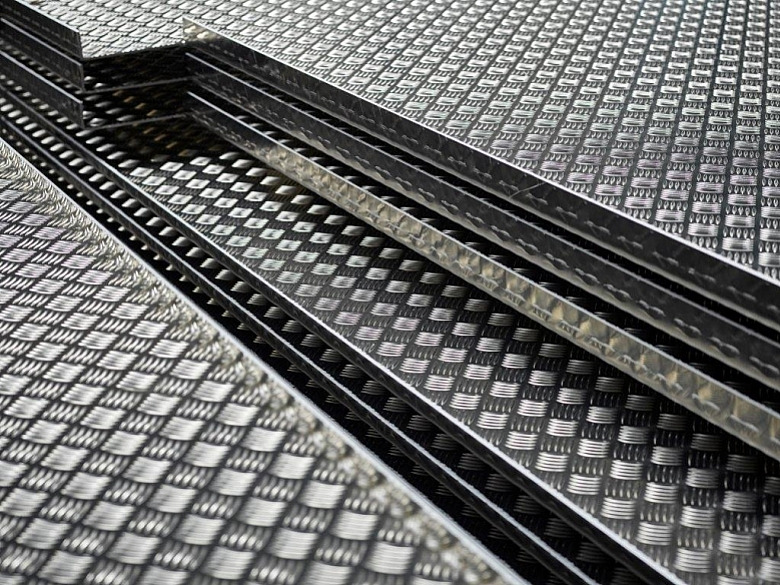

Aluminium

Alinco cuts, bends, welds, and processes aluminum projects. It’s simple: anything Alinco can produce in stainless steel can also be made in aluminum.

Alinco cuts, bends, welds, and processes projects in aluminum. Simply put, anything Alinco can produce in stainless steel can also be made in aluminum.

Aluminum is a material with many advantages (lightweight, easily extrudable, fairly corrosion-resistant, recyclable, etc.), but it also presents challenges compared to steel or stainless steel. Laser cutting is more complex, the material is less dimensionally stable during bending or plate rolling, and the welding process is more intricate. Therefore, expertise is essential when working with aluminum.

Sheet Metal and Construction

The standard grade we work with is Alu AlMg3.

Welding Services

Aluminum welding is considered "more difficult" for the following reasons:

- You need a suitable welding station.

- Aluminum conducts heat faster than stainless steel or iron, which means more heat is needed during the welding process.

- There is a higher risk of cracks and poor welds compared to stainless steel and iron, so expertise is very important.

- Aluminum creates a heavier weld seam, which often makes it more challenging aesthetically.

- Grinding the weld significantly reduces its strength.

Alinco has sufficient expertise to execute aluminum welding properly. For welding thicker materials, we have welding stations available with a capacity of up to 400A.

Alinco primarily works with Alu AlMg3 = AW 5457.