Grinding weld seams

Grinding down weld seams is still a highly requested finish at Alinco, especially for ground, brushed, or sanded stainless steel. This method offers both aesthetic and functional benefits and provides good roughness values. This finish is very common for pharmaceutical applications and high-end machine enclosures.

Common finishes

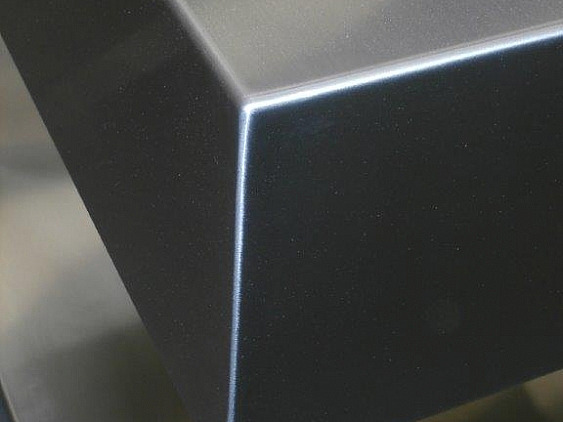

- Ground outer corners, pickled inner corners

This is the most common finish. The outer corners are ground, and the sanding direction is restored, while the inner corners remain pickled and are not ground. - Ground outer and inner corners

This finish includes grinding both the outer and inner corners. Naturally, grinding inner corners is more costly. For finely welded inner corners, the aforementioned combination of ground outer corners and pickled inner corners is often sufficient. - Finely welded, pickled weld seams, not ground

Although the base plate is ground, the weld seams do not necessarily need to be ground. This method is rarely chosen for outer corners.

Cost consideration

- The more grinding work required, the higher the costs. We offer flexible options so you can find the right balance between aesthetics, functionality, and budget.