Pickling and passivating at Alinco

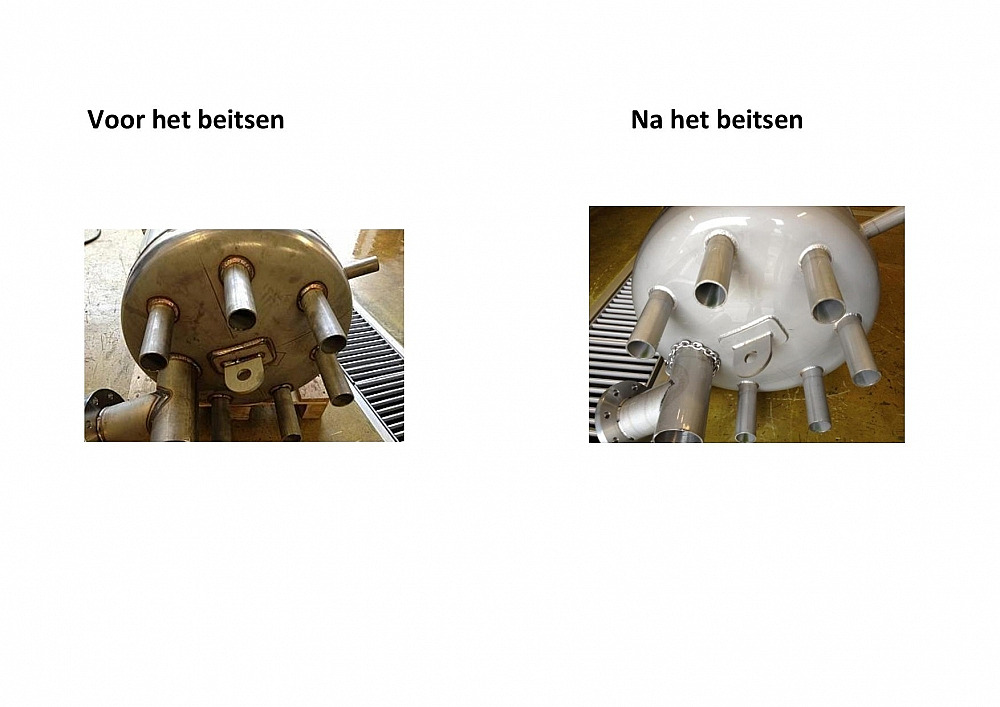

Pickling and passivating are high-quality post-treatments for stainless steel that ensure excellent cleaning and corrosion resistance, though they are not always the most aesthetic option.

At Alinco, we have advanced pickling installations to meet diverse needs:

- Full bath pickling: Pickling bath for full bath pickling up to 4470x1480x1000mm.

- Spray pickling: Spray pickling installation for large pieces with a crane in a hall of 12x8 meters.

- Electrolytic pickling: Various devices for local pickling of weld seams only.

For pickling of very large pieces, we work with our sister company Deprest, which has a pickling hall of 20x12 meters with two cranes.

Advantages of pickling:

- High-Quality Post-Treatment: Effectively removes all contaminants and improves corrosion resistance.

- Cost-Effective: Relatively low costs compared to other post-treatments.

- Minimal impact on roughness values: Maintains the original roughness of the material, with only minimal fluctuations.

Disadvantages of pickling:

- Aesthetics: While pickling is functional, it is less aesthetic. With the right expertise, however, it can also be used for aesthetic applications.

What is pickling and passivating? Technically Explained.

Pickling of stainless steel (inox) is a chemical process that removes a thin layer from the surface to eliminate contaminants and oxide scales.

This process helps restore and improve the material's corrosion resistance. It is applied because (corrosion) damage can occur during the production process. The main causes are:

- Welding: Can create a thick weld oxide layer with a chromium-deficient zone, which is less resistant to local corrosion.

- Grinding, Sanding, Transport: Can contaminate the material with foreign iron.

Pickling removes chromium-deficient zones and foreign iron, restoring corrosion resistance. Depending on the size of the material, this can be done by:

- Local Application of Pickling Paste: With a brush, e.g., for weld seams.

- Electrolytic Pickling: With a device (also local for weld seams).

- Immersion in Pickling Fluid.

- Spraying with Pickling Spray: For large surfaces.

After treatment, it is important that the material is thoroughly rinsed with water. The rinse water must be carefully collected and picked up by a certified processor.

Passivating:

After the pickling process, the surface of the stainless steel is 'active' and the protective chromium oxide layer needs to reform. This process, known as passivation, occurs spontaneously in contact with air but takes 24 to 48 hours. Passivation can be accelerated with chemical products. Properly executed natural passivation is qualitatively equal to chemical passivation. It is essential that this process takes place under optimal conditions, as even a small iron contamination can disrupt the process.

Pickling and passivating ensure that stainless steel retains its corrosion resistance and extends the material's lifespan, which is crucial for applications in various industrial sectors.

Both Alinco and Deprest mainly pickle for their own production but occasionally for third parties. Goods must be delivered pickling-ready, free of gaps, and unassembled. Customer packaging materials are reused.