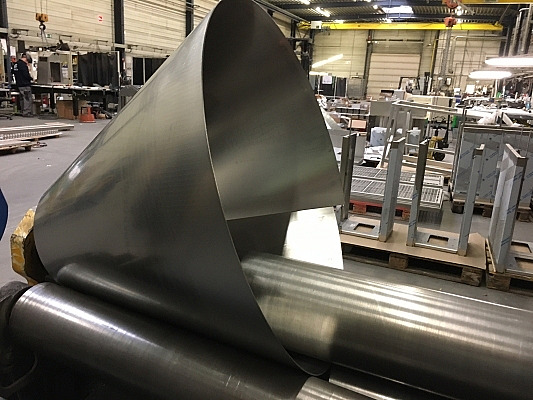

Flattened edges in sheet rolling

In fact, Alinco does a fair amount of rolling work for others. Just cut and roll; the customer then takes care of the subsequent processing such as welding and finishing. No problem, Alinco offers a vast range of options with regard to sheet rolling. With many construction workshops among our customers, it is logical that they would want to take care of the welding themselves.

In that case, please keep the following in mind:

- Centring always produces flattened edges. We always do our best, but since we cannot weld the longitudinal seam ourselves, we don’t have the possibility to either roll it further or hammer it more... Getting that right is in the hands of the workshop that takes over from us.

- The result is not always 100% successful, especially with difficult cones. There, too, it is up to the welder’s skill to pull that right first – the same applies to square rounding.

- Rolling is never 100% dimensionally stable. Especially in the case of thin sheets. If, for example, you bend a rolled sheet with a diameter of 500 mm and thickness of 1.5 mm, and place it immediately on a pallet, the 500 mm diameter has already been slightly elongated into an egg shape.

When in doubt, you can always consider having the longitudinal seam welded at Alinco or at least have the longitudinal seam tack welded.

Remember also to indicate the desired welding preparation. Do you want a beveled or straight edge? We cannot know that. However, the weld edge preparation should be performed beforehand; once the sheet is centred, this is much more difficult.

Karine De Bie