3D Printing at Alinco – In-House Prototype Development

At Alinco, we also have a 3D printer, which we use internally to print prototypes for our customers. If you have any questions or interest, feel free to mention it in your price request.

Please note: 3D printing is a supporting service within a metalworking project. We do not offer a commercial 3D printing service for standalone external print jobs.

At Alinco, we are fully committed to innovation and customer-focused customization. Our in-house 3D printer is a valuable addition to our service offering, enabling us to quickly and efficiently produce functional prototypes and support components. This strengthens the design process and shortens lead times for your projects.

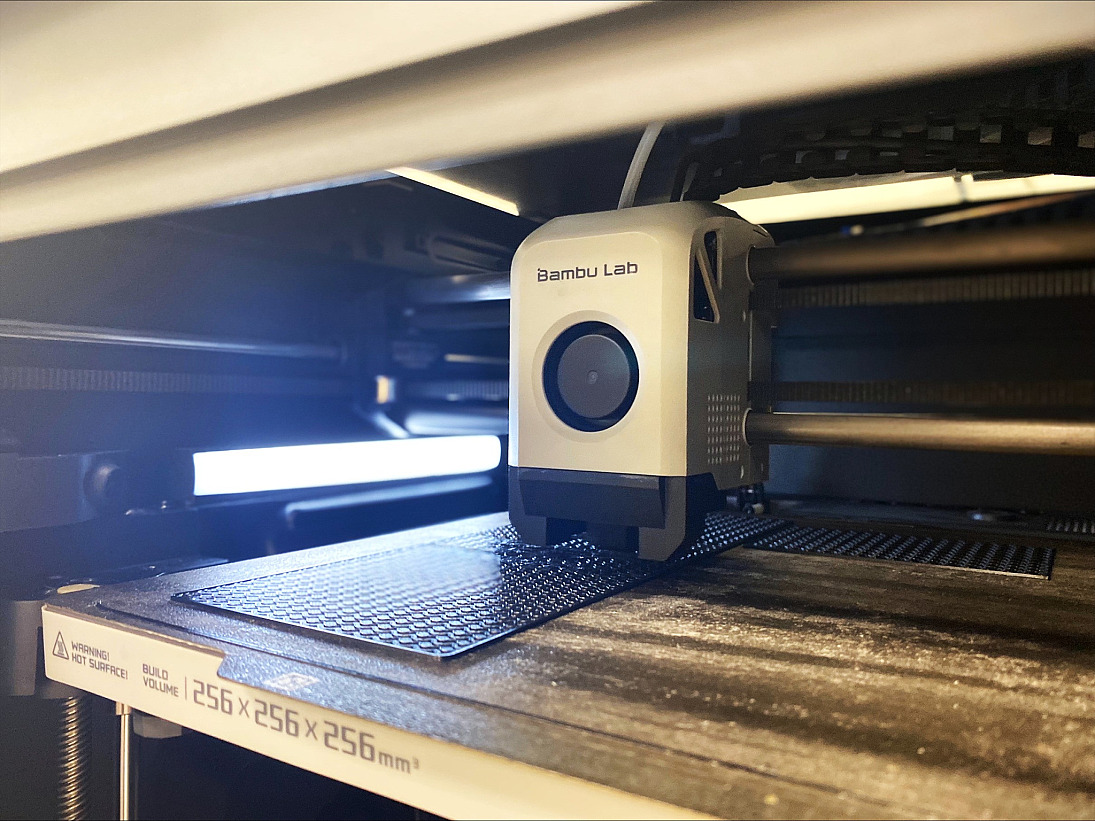

Specifications of our 3D printer

- Printer type: FDM (Fused Deposition Modeling)

- Print volume: max. 256 x 256 x 256 mm

- Layer height / resolution: adjustable from 0.1 mm to 0.3 mm

- Nozzle diameter: 0.2 – 0.8 mm

Available materials

We use various thermoplastic filaments, each tailored to the application:

- PLA (Polylactic Acid)

- Standard material for quick and affordable prototypes

- Biodegradable* and odorless

- PETG (Polyethylene Terephthalate Glycol)

- Stronger than PLA, good chemical resistance

- Suitable for functional parts and test assemblies

- ABS (Acrylonitrile Butadiene Styrene) (on request)

- High impact and temperature resistance

- Less suitable for fine details but very robust

- Other technical materials (such as TPU, nylon, composites) available on request for specific projects

*Biodegradable only under industrial composting conditions, not in nature or home compost.

Applications & advantages

Our 3D printer is used as a supporting technology within our metalworking process.

Typical applications include:

-

Part prototypes prior to metal production

-

Fastening aids, auxiliary frames, or assembly jigs

-

Scale models for design visualization

-

Test forms for fit and functionality

-

Internal tools or fixtures to support production processes

Customer benefits:

-

Faster feedback cycles: early validation of test forms or designs

-

Lower development costs: quicker detection and correction of errors

-

Shorter lead times: fewer delays in technical decisions or with complex parts

-

Optimized metalworking: increased accuracy and better preparation during the design stage

How to request?

Are you interested in a 3D printed prototype or want to know if your project qualifies?

Simply mention this in your quote request or inquiry. Our technical department will review the possibilities with you and provide a tailored proposal.

Please note:

3D printing is a supporting service within a metalworking project. We do not offer a commercial 3D printing service for standalone external print jobs.