Deburring

Before deburring:

Even with the most precise cutting techniques, sharp edges can occur. By carefully deburring, we make these edges smooth and safe. This not only increases user-friendliness and safety but also guarantees a high-quality finish and optimal preparation for further treatments such as brushing, polishing or painting.

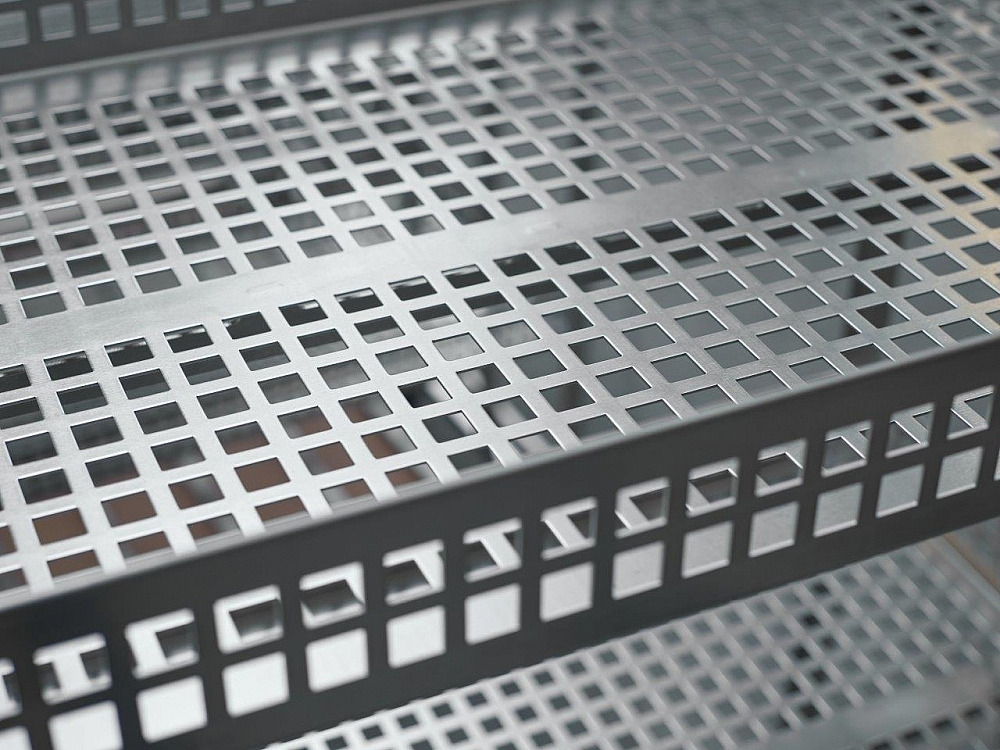

After deburring:

Through this process, sharp edges are made smooth and safe, significantly reducing the risk of cuts or damage. In addition, deburring greatly contributes to user-friendliness and increases the durability of the product. A smooth and precisely finished surface also forms the ideal basis for subsequent treatments such as brushing, polishing or painting.

In this way, we guarantee not only safe and comfortable use but also a high-quality final finish that meets the highest quality standards.

Our deburring machines:

Thanks to our wide and versatile range of deburring machines, from large abrasive belt systems to a simple grinding wheel, we can effortlessly handle everything: from the smallest parts to the largest plates, and even the removal of laser tags is carried out without any problem.